New owner, new era for Transportable Shade Sheds Australia

Transportable Shade Sheds Australia (TSS) is now under new ownership with a team committed to revitalising the brand and fostering positive change. Moggy’s Group—a family-owned

Transportable Shade Sheds Australia is an innovative and award-winning national manufacturing company based in Mackay Queensland delivering Australia-wide.

Providing peace of mind.

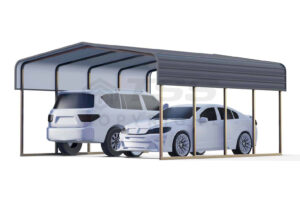

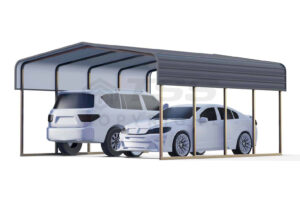

Our Range

An affordable solution for protecting a diverse range of valuable assets.

A multi-purpose structure with insulated walls and power. An ideal solution for storage, offices and more.

Certified storage options for dangerous materials, designed to meet Australian standards.

How To

Complete the enquiry form on the website for your desired product and one of our team members will be in touch shortly to place your order. Alternatively contact our team directly on 1300 667 433 to get any of your questions answered and place your order.

Once your order is placed you will receive an invoice number from your dedicated product technician. Use this number to track the progress of your Shade Shed!

Upon delivery, your pre-engineered Shade Shed includes everything you need to erect your new Shade Shed. With our patented technology of swaging the frames, it’s a simple process of sliding the frames together!

We use heavy duty Galvanised Australian Steel for all of our products.

We supply Certified Engineer Drawings for our entire Shade Shed Range.

We offer the full Colorbond range for all the relevant Shade Sheds products.

We use Galvanised Steel for all of our products to prevent corrosion.

We offer multiple grounding options that are suitable for a diverse range of environments.

Our products manufactured in our workshop, based in Mackay Queensland. Plus, we deliver Australia wide!

Our patented Swaged Fitted Frames are made to be quick and easy to assemble.

Our patented technique of bending the steel frames, makes our product 30% stronger than anything else on the market!

Transportable Shade Sheds Australia (TSS) is now under new ownership with a team committed to revitalising the brand and fostering positive change. Moggy’s Group—a family-owned

At Transportable Shade Sheds, we know how important it is to choose the right materials for any project. That’s why when you want a particular

Caravans are a great way to explore the open road while enjoying the comforts of home. You don’t have to go far to see one

"*" indicates required fields